Detailed Product Description and Applications

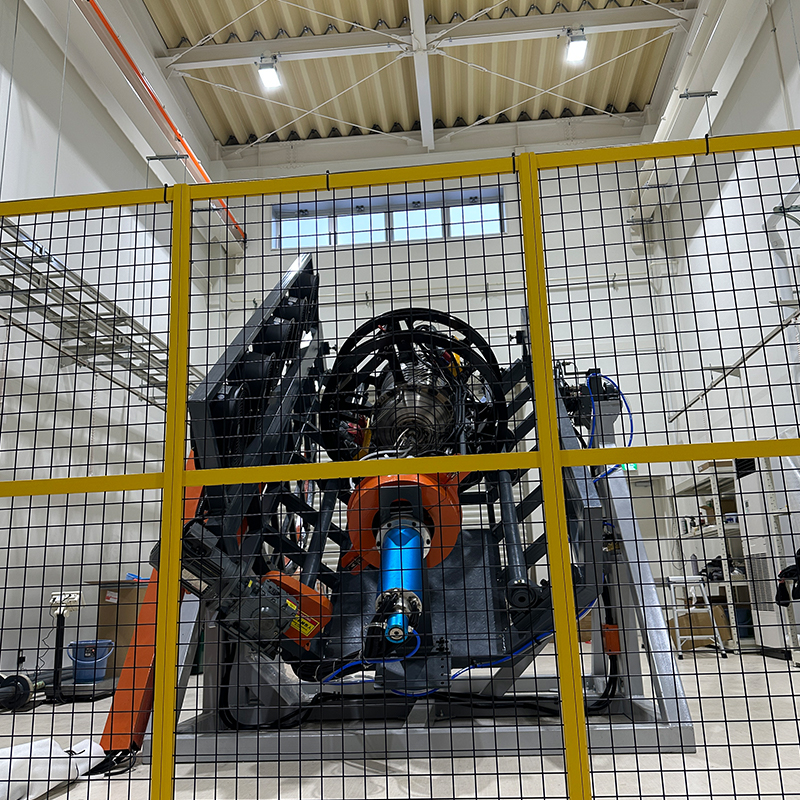

The hydrogen gas cylinder rotational molding mold is optimized for demanding industrial conditions and long production cycles.

-

Structural Design

- Engineered for cylindrical hollow products with smooth internal surfaces

- Optimized mold geometry to support uniform material distribution

- Reinforced structure to withstand repeated heating and cooling cycles

-

Material Compatibility

- Suitable for rotational molding of HDPE, cross-linked polyethylene (XLPE), and other rotomolding-grade polymers

- Supports materials commonly used for hydrogen containment liners and outer shells

-

Manufacturing Precision

- High dimensional accuracy to ensure consistent cylinder volume and wall thickness

- Stable mold closure system to reduce deformation during rotation

-

Production Efficiency

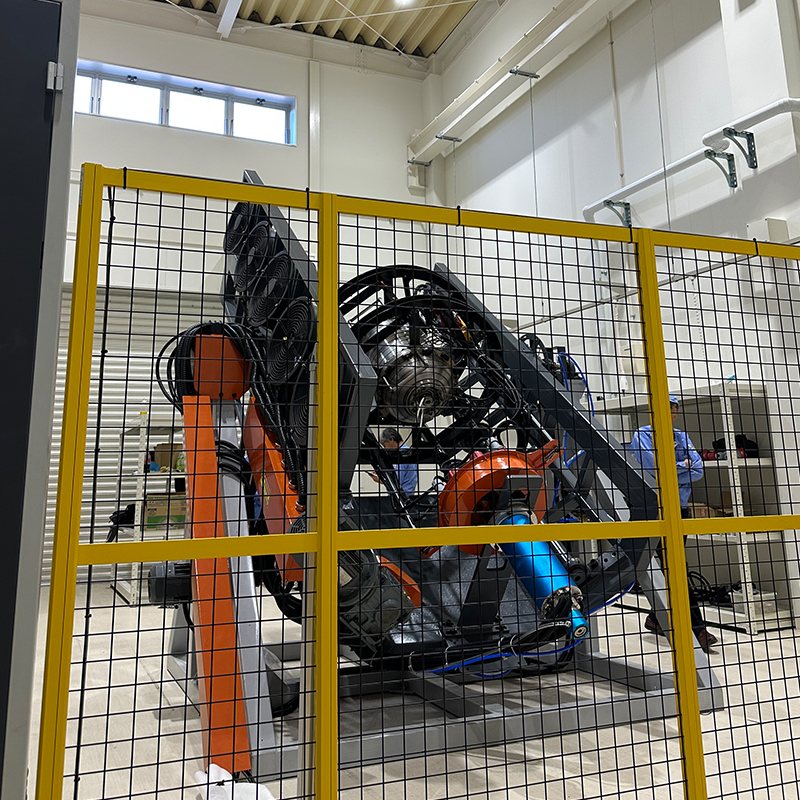

- Designed for standard rotational molding machines

- Supports automated and semi-automated production lines

-

Typical Applications

- Hydrogen gas cylinder outer shells

- Protective casings for composite hydrogen tanks

- Industrial gas storage containers

- Experimental and prototype hydrogen storage vessels

Key Technical Advantages

- High thermal stability under continuous heating cycles

- Low maintenance requirements due to robust mold construction

- Long service life suitable for high-frequency production

- Customizable mold dimensions to match specific hydrogen cylinder specifications

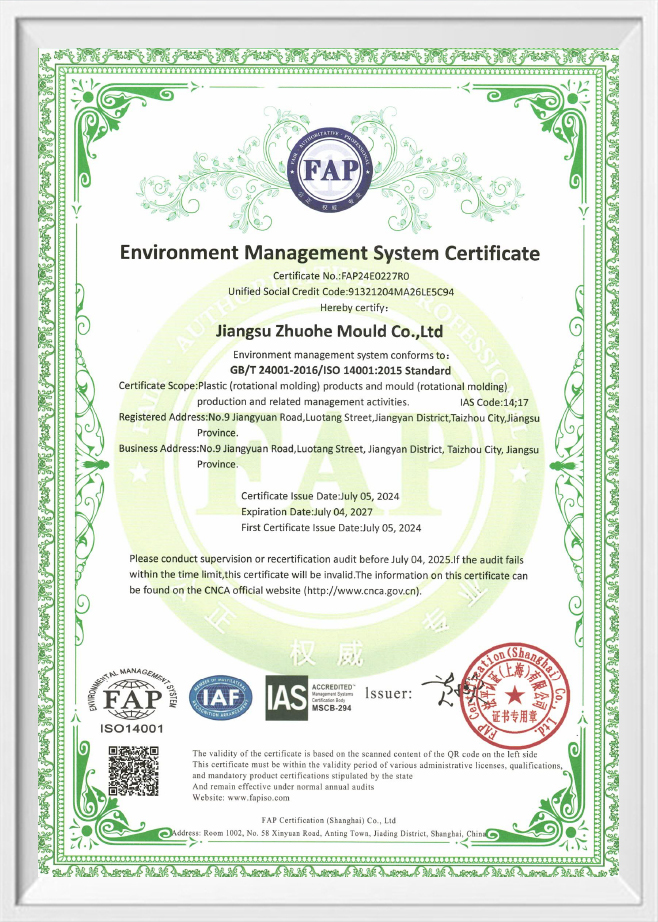

Quality and Safety Considerations

The hydrogen gas cylinder rotational molding mold is designed with safety-oriented production in mind.

- Supports production of cylinders with uniform stress distribution

- Minimizes internal defects such as voids and weak points

- Contributes to improved product reliability in hydrogen-related environments

Comparison with Similar Rotational Molding Molds

| Comparison Item |

Hydrogen Gas Cylinder Rotational Molding Mold |

Standard Storage Tank Rotational Mold |

General Hollow Container Mold |

| Target Product |

Hydrogen gas cylinders |

Liquid storage tanks |

Generic hollow containers |

| Structural Precision |

High, cylinder-specific |

Medium |

Medium |

| Wall Thickness Control |

Excellent |

Good |

Moderate |

| Application Safety Requirement |

Very high |

High |

Standard |

| Customization Level |

High |

Medium |

Low |

| Production Stability |

Excellent for long cycles |

Good |

Good |

Customization and Design Support

The hydrogen gas cylinder rotational molding mold can be tailored to specific project requirements.

- Adjustable cylinder diameter and length

- Optional surface finish treatments

- Mold design optimization based on production volume and material selection

Frequently Asked Questions (FAQ)

Q1: What is the main purpose of a hydrogen gas cylinder rotational molding mold?

A: The mold is specifically designed to manufacture hollow plastic components used in hydrogen gas cylinders, ensuring consistent wall thickness, structural stability, and production reliability.

Q2: Which rotational molding materials are suitable for this mold?

A: The mold is compatible with commonly used rotational molding polymers such as HDPE and XLPE, which are widely applied in hydrogen storage-related components.

Q3: Can this mold be customized for different hydrogen cylinder sizes?

A: Yes, the mold can be customized in terms of diameter, length, wall thickness design, and surface finish to meet different hydrogen gas cylinder specifications.

Q4: Is the mold suitable for continuous industrial production?

A: Yes, it is designed for repeated heating and cooling cycles and is suitable for continuous or high-frequency industrial rotational molding operations.

Q5: How does this mold contribute to product safety?

A: By ensuring uniform material distribution and minimizing internal defects, the mold helps produce cylinders with stable mechanical performance and improved reliability.

Maintenance and Service Life

With proper operation and routine inspection, the hydrogen gas cylinder rotational molding mold offers a long service life. Regular cleaning, controlled heating cycles, and correct demolding practices help maintain dimensional accuracy and surface quality over extended production periods.

The hydrogen gas cylinder rotational molding mold is a specialized solution for manufacturers involved in hydrogen energy and industrial gas applications. Its precise design, production stability, and customization capability make it a reliable choice for producing high-quality hydrogen gas cylinder components through rotational molding.

English

English 中文简体

中文简体 русский

русский Español

Español