Why is the mold of agricultural machinery parts important? See how Jiangsu Zhuohe Mould leads the industry with innovation!

As the process of agricultural mechanization continues to accelerate, the importance of agricultural machinery parts molds as a key link in supporting the upgrading of agricultural equipment is becoming increasingly prominent. Jiangsu Zhuohe Mould Co., Ltd., as a leader in the field of agricultural machinery parts molds, is leading the industry to a higher level with its profound technical background and spirit of continuous innovation.

Zhuohe Mould, formerly Suzhou Zhuohe Mould Technology Co., Ltd., has been deeply involved in the development and production of roto-molding molds and parts since its establishment in 2015, and has accumulated rich industry experience. The strategic relocation and renaming in 2021 not only marks the expansion of the company's scale, but also heralds its comprehensive upgrade in technology, market and service. The new factory covers an area of more than 12,000 square meters and is equipped with advanced production equipment, including multiple CNC centers and roto-molding machines. The annual production capacity has been significantly enhanced, providing a solid guarantee for the mass production and high-quality production of agricultural machinery parts molds.

Zhuohe Mould is particularly good at agricultural machinery parts moulds. Its product line covers multiple fields such as engineering vehicle fuel tanks/water tanks, clean and environmentally friendly boxes, etc., especially the customized development of agricultural machinery parts, which demonstrates the company's strong technical strength and ability to respond to the market quickly. These high-quality moulds not only improve the precision and durability of agricultural machinery parts, but also promote the overall performance of agricultural machinery, providing strong support for the efficient and environmentally friendly operation of modern agriculture.

It is particularly worth mentioning that Zhuohe Mould also actively participates in major national events, such as the production of supporting products for the 2008 Beijing Olympic Games and the 2010 Shanghai World Expo. This is not only a high recognition of the company's strength, but also reflects its stable performance and outstanding contribution in large-scale projects.

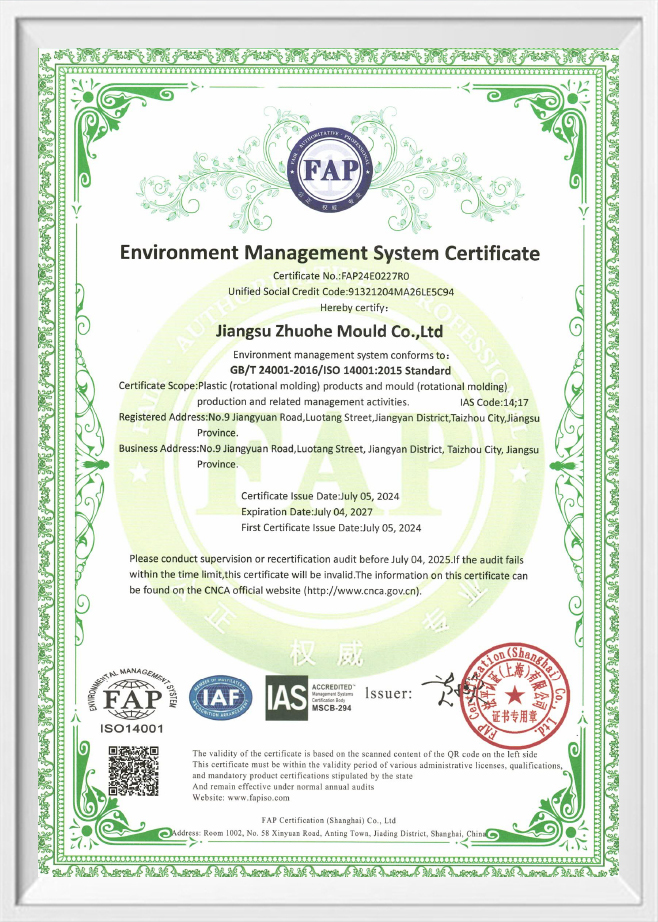

In terms of quality management, Zhuohe Mould strictly implements the ISO9001:2015 quality management system to ensure that every product can meet international first-class standards. At the same time, the company has also passed the ISO14001:2015 environmental management and ISO45001:2015 occupational health and safety management system certification, demonstrating its commitment to social responsibility and corporate sustainable development.

With the continuous advancement of agricultural modernization, the agricultural machinery parts mold industry will usher in a broader development space. Jiangsu Zhuohe Mould Co., Ltd. will continue to uphold the concept of "quality-oriented, innovation-first", increase R&D investment, optimize product structure, and improve service quality, so as to contribute more to the sustainable and healthy development of my country's agricultural machinery parts mold industry.

English

English 中文简体

中文简体 русский

русский Español

Español